News

Can Silicon Carbide Heating Elements Be Used In A Vacuum?

You're likely asking whether silicon carbide (SiC) heating elements are a good fit for vacuum furnaces or processes. Short answer: yes, with important caveats. SiC offers high-temperature capability and excellent radiative performance, but vacuum service demands...

What Is The Difference Between Starbar And Moly-D Heating Elements?

When you're specifying industrial heaters, the choice between Starbar and Moly‑D heating elements matters. Both families deliver electric resistance heat for process equipment, but they differ in construction, operating limits, and optimal applications. In this text...

Maintenance Checklist For High-Temperature Elements

When your process relies on heat, you can't afford surprises. This maintenance checklist for high temp elements helps you spot issues early, keep energy use in check, and extend service life. Whether you run electric resistance elements in furnaces, ovens, kilns, or...

Heating Element Layout And Uniformity

When you design a heater, getting the temperature "about right" isn't enough. Heating element layout and uniformity determine whether your process meets spec, your adhesive cures evenly, or your optics stay distortion‑free. A few millimeters of extra trace width, a...

Selecting Heater Materials By Furnace Atmosphere

If you've ever lost a heater element before its time, you know the culprit is often the gas it lived in, not the wattage on the nameplate. Selecting heater materials by furnace atmosphere is the fastest way to boost element life, stabilize temperature control, and...

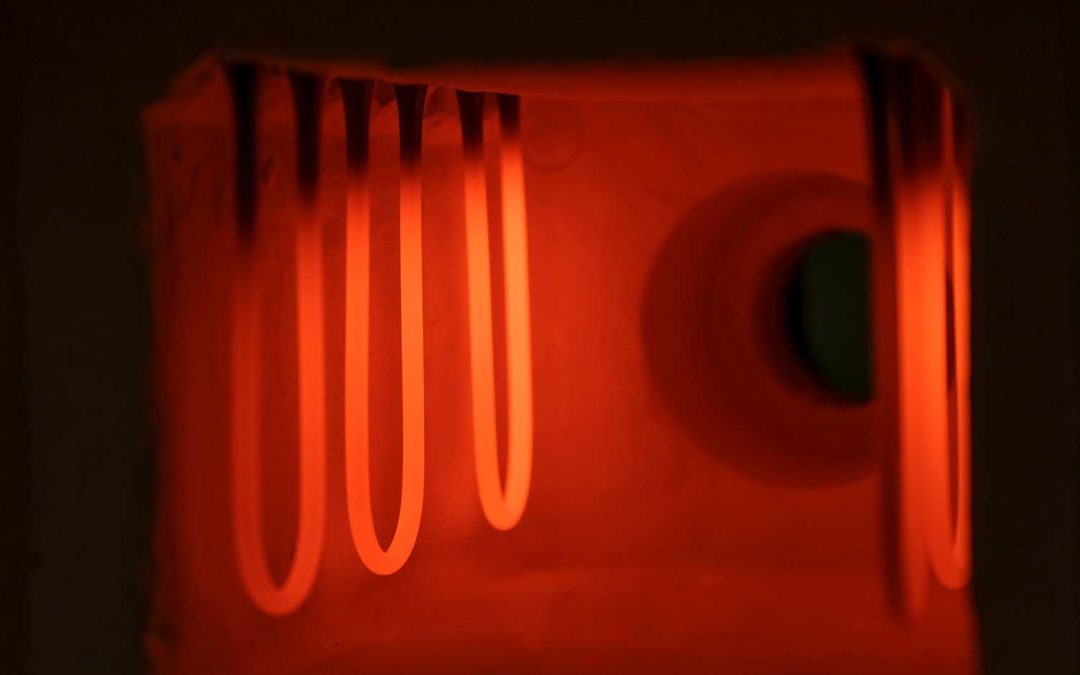

Silicon Carbide Element Types Explained

If you're choosing or replacing furnace heaters, you've likely run into a wall of jargon: rods, dumbbells, U-legs, spiral grooves, plus grades like recrystallized vs reaction-bonded. This guide gives you silicon carbide element types explained in plain language so you...

Molybdenum Disilicide Heating Elements Temperature Limit

Moly-D (Molybdenum Disilicide) (MoSi₂ ) heating elements have become key components in high-temperature applications and material processing due to their superior performance and durability. Understanding their temperature limits is crucial for ensuring optimal...

Silicon Carbide Heating Elements Temperature Limit

When it comes to efficient heating solutions in high-temperature environments, silicon carbide (SiC) heating elements stand out as a formidable choice. Understanding their temperature limits is crucial for industries that rely on precise thermal control. Let's jump...

How to Extend the Lifespan of Your Industrial Heating Elements

Industrial heating elements play a pivotal role in various manufacturing processes, from cooking to metal processing. Yet, they often face extreme conditions that can significantly impact their performance and longevity. To avoid costly downtime and replacements, you...

Choosing The Right Heating Element For High-Temperature Furnaces: Starbar Vs. Moly-D

When it comes to high-temperature furnaces, choosing the right heating element can make a significant difference in your processes. With options like Starbar Heating Elements and Moly-D Heating Elements, you have two robust choices that cater to various applications....

How to Choose the Right Heating Element for High-Temperature Applications: A Complete Guide

When you're working in hot temperatures, the heating element that you're using can be the make-or-break factor in your operation. No element is equally constructed—ceramic, metallic, silicone, and infrared elements all respond differently under rugged conditions. The...

Why Consistent Temperature Control is Crucial in Industrial Heating Systems for Efficiency and Quality

When it comes to industrial heating systems, maintaining a steady temperature isn’t just a convenience—it’s essential. The moment temperatures fluctuate, you’re dealing with wasted energy, rising operational costs, and even potential damage to your equipment. But when...

Exploring the Advantages of Using Advanced Materials for Heating Elements: Efficiency & Durability

When it comes to heating elements, the materials used can make all the difference in performance, efficiency, and durability. Traditional materials might get the job done, but advanced materials are revolutionizing the way heating systems operate, offering benefits...