RR Element

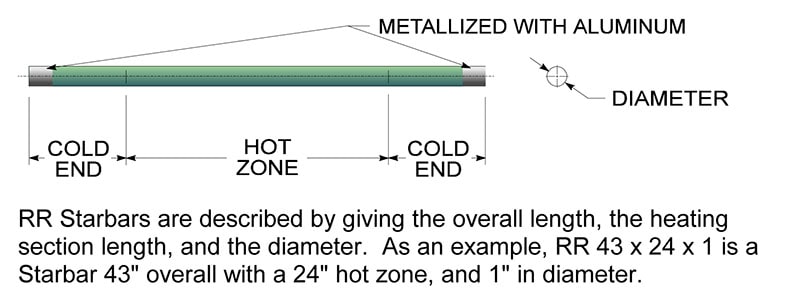

The RR Starbar is a resistance type silicon carbide heating element. Starbars are rod shaped or tubular depending on the diameter. They have a central heating section referred to as a hot zone and two terminal sections called cold ends. There are two types of RR Starbars. (1) The cold ends are impregnated with silicon metal - referred to as one piece, and (2) low resistance cold ends which are furnace welded to the hot zone - referred to as a three piece or LRE (Low Resistance End) type. This lower electrical resistance cold end causes them to operate at a lower temperature. The extremities of the elements are metallized with aluminum to provide a low resistance contact surface to which the electrical connections are made using braided aluminum straps.

RR and RA Brochure

(PDF, 629KB)

Sizing Breakdown

| Item # | Nominal Diameter | Max Overall Length | Hot Zone (Electrical Resistance) | Cold End (Electrical Resistance) |

|---|---|---|---|---|

| RR-3/8-10 | 3/8 Inch 10 mm | 26 Inch 660 mm | 0.34856 Ohms/Inch 0.01372 Ohms/mm | 0.01743 Ohms/Inch 0.000686 Ohms/mm |

| RR-7/16-11 | 7/16 Inch 11 mm | 36 Inch 915 mm | 0.28700 Ohms/Inch 0.01130 Ohms/mm | 0.01282 Ohms/Inch 0.000505 Ohms/mm |

| RR-1/2-13 | 1/2 Inch 13 mm | 42 Inch 1090 mm | 0.19410 Ohms/Inch 0.00764 Ohms/mm | 0.00982 Ohms/Inch 0.000387 Ohms/mm |

| RR-5/8-16 | 5/8 Inch 16 mm | 50 Inch 1250 mm | 0.12450 Ohms/Inch 0.00490 Ohms/mm | 0.00631 Ohms/Inch 0.000248 Ohms/mm |

| RR-3/4-19 | 3/4 Inch 19 mm | 62 Inch 1575 mm | 0.08790 Ohms/Inch 0.00346 Ohms/mm | 0.00433 Ohms/Inch 0.00017 Ohms/mm |

| RR-1-25 | 1/1 Inch 25 mm | 74 Inch 1900 mm | 0.05100 Ohms/Inch 0.00200 Ohms/mm | 0.0025 Ohms/Inch 0.000098 Ohms/mm |

| RR-1-1/4-32 | 1-1/4 Inch 32 mm | 130 Inch 3300 mm | 0.03200 Ohms/Inch 0.00126 Ohms/mm | 0.00171 Ohms/Inch 0.000067 Ohms/mm |

| RR-1-3/8-35 | 1-3/8 Inch 35 mm | 130 Inch 3300 mm | 0.02693 Ohms/Inch 0.00106 Ohms/mm | 0.00135 Ohms/Inch 0.000053 Ohms/mm |

| RR-1-1/2-38 | 1-1/2 Inch 38 mm | 130 Inch 3300 mm | 0.02120 Ohms/Inch 0.00083 Ohms/mm | 0.00117 Ohms/Inch 0.000046 Ohms/mm |

| RR-1-3/4-45 | 1-3/4 Inch 45 mm | 130 Inch 3300 mm | 0.01650 Ohms/Inch 0.00065 Ohms/mm | 0.00082 Ohms/Inch 0.000032 Ohms/mm |

| RR-2-1/8-54 | 2-1/8 Inch 54 mm | 228 Inch 5800 mm | 0.01490 Ohms/Inch 0.00059 Ohms/mm | 0.00075 Ohms/Inch 0.00003 Ohms/mm |

| RR-2-1/2-64 | 2-1/2 Inch 64 mm | 228 Inch 5800 mm | 0.00930 Ohms/Inch 0.00037 Ohms/mm | 0.00055 Ohms/Inch 0.000022 Ohms/mm |

| RR-2-3/4-70 | 2-3/4 Inch 70 mm | 228 Inch 5800 mm | 0.00730 Ohms/Inch 0.00029 Ohms/mm | 0.00052 Ohms/Inch 0.000020 Ohms/mm |

Mounting

There are no restrictions on the mounting positions of Starbars, although horizontal and vertical orientation are the more common. Extreme caution should be used when mounting to ensure that the Starbars are not placed in tension. There should be adequate freedom to allow for the furnace and Starbars to expand and contract independently.

When mounting Starbars vertically, they must be supported on the lower end by electrically insulated supports, or from above using support pins on an isolating plate of sufficient strength to support the weight of the elements.

The Starbar ends should extend beyond the furnace cold face by a minimum distance of 3 to 4 inches or 3 × the element diameter (whichever is greater). When using sealed terminal boxes, extend the cold ends by a minimum of 4-5 × the element diameter.

Starbars should have their heating sections centered in the furnace chamber so that no portion of the heating section extends into the furnace wall. A conical or truncated cone shaped recess 1/2 inch (13mm) deep is sometimes located on each interior wall where the Starbar passes through. This allows the hot zone to radiate properly and may help maintain a uniform temperature in the kiln.

| Table B Recommended Minimum Refractory Hole Size |

|||||||||||

| Minimum Hole Diameter Based on Refractory Wall Thickness | |||||||||||

| Starbar Diameter |

100 | 150 | 200 | 300 | 400 | 3 | 5 | 6.5 | 9 | 13.5 | |

| mm | Inch | mm | mm | mm | mm | mm | Inch | Inch | Inch | Inch | Inch |

| 10 | 3/8 | 15 | 15 | 16 | 9/16 | 9/16 | 5/8 | ||||

| 11 | 7/16 | 16 | 17 | 18 | 20 | 5/8 | 11/16 | 11/16 | 3/4 | ||

| 13 | 1/2 | 18 | 19 | 20 | 22 | – | 11/16 | 3/4 | 3/4 | 13/16 | – |

| 16 | 5/8 | 21 | 22 | 23 | 25 | – | 13/16 | 7/8 | 7/8 | 15/16 | – |

| 19 | 3/4 | 25 | 25 | 26 | 28 | – | 15/16 | 1 | 1 | 1-1/16 | – |

| 25 | 1 | 31 | 32 | 33 | 35 | 37 | 1-3/16 | 1-3/16 | 1-1/4 | 1-1/4 | 1-7/16 |

| 32 | 1-1/4 | 38 | 39 | 40 | 42 | 44 | 1-1/2 | 1-1/2 | 1-9/16 | 1-9/16 | 1-11/16 |

| 35 | 1-3/8 | 41 | 42 | 43 | 45 | 47 | 1-5/8 | 1-5/8 | 1-11/16 | 1-11/16 | 1-13/16 |

| 38 | 1-1/2 | 44 | 44 | 46 | 48 | 50 | 1-3/4 | 1-3/4 | 1-13/16 | 1-7/8 | 1-15/16 |

| 45 | 1-3/4 | 51 | 52 | 53 | 55 | 57 | 2 | 2-1/16 | 2-1/16 | 2-1/8 | 2-3/16 |

| 54 | 2-1/8 | 61 | 62 | 63 | 65 | 67 | 2-3/8 | 2-7/16 | 2-7/16 | 2-1/2 | 2-9/16 |

| 64 | 2-1/2 | 72 | 72 | 72 | 74 | 76 | 2-13/16 | 2-13/16 | 2-13/16 | 2-7/8 | 3 |

| 70 | 2-3/4 | 79 | 79 | 79 | 81 | 83 | 3-1/8 | 3-1/8 | 3-1/8 | 3-3/16 | 3-1/4 |

Specifications

Operating Temperatures

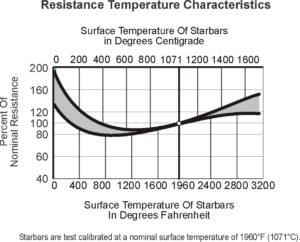

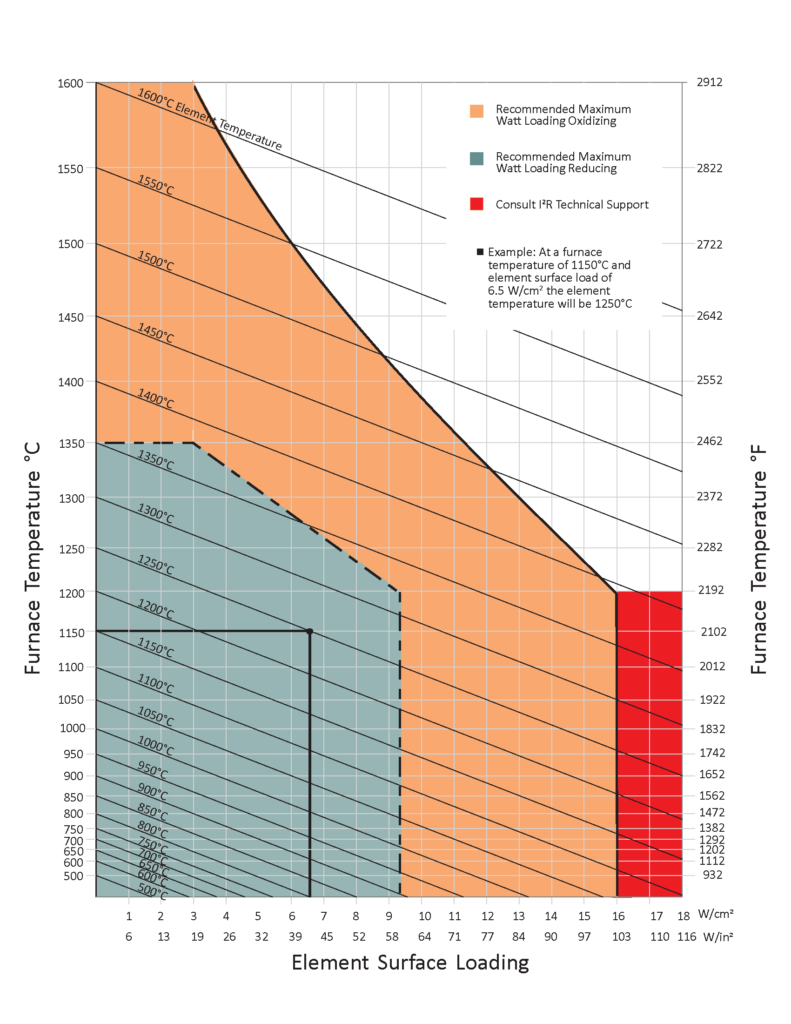

In clean dry air, the one piece Starbars can be operated at furnace control temperatures up to 2912°F (1600°C), the three piece Starbar up to 2600°F (1425°C). In inert atmospheres of argon or helium, one piece elements may be operated to 3092°F (1700°C). For atmospheres containing water vapor, alkali metal species, flux vapors or oxygen enrichment, we recommend our LMA infusion glaze coated RR elements, or elements of type HDS, TW, SE, SER or SEU. In reducing atmospheres the maximum operating temperature is 2500°F (1370°C), see Figure 1. There is a protective coating of silicon dioxide on the silicon carbide. Hydrogen reduces this coating and causes the Starbar to deteriorate. Very dry or very wet hydrogen is detrimental to long service life.

Nitrogen atmosphere applications are limited to 2500°F (1370°C) and 30 watts per square inch (5 watts per square centimeter) maximum surface watt loading. Too high of a surface temperature will result in a silicon nitride reaction. A thermally insulative layer forms around the Starbar resulting in very high surface temperatures which damage the Starbars.

Engineering Information

Superior Performance

Starbars will give you superior performance due to their high density — approximately 2.52 g/cm3. This gives the Starbar very slow aging characteristics and high strength.

interchangeability

Starbars are premier grade high performance silicon carbide elements, and the only silicon carbide heating elements manufactured in the United States. Starbars can also be manufactured in special sizes and resistance values to replace elements supplied by other manufacturers in Asia and Europe. It is important to provide the nominal electrical resistance when ordering Starbars. Please contact us, before attempting to substitute the RR Starbars for spiral type SE Starbars.

Electrical Characteristics

The silicon carbide Starbar is a linear type resistance heater that converts electrical energy to heat energy – Joule’s Law W = I2 x R, (W = power in watts, I = current in amperes, R = resistance in ohms).

Electrical Loading

Starbars are not sized to a specific wattage output like metallic heating elements. The amount of energy that a Starbar is capable of converting from electrical to heat energy depends on the ambient furnace temperature and atmosphere in which the Starbar.

Power Supply

In the previous paragraph we explained how to calculate the recommended wattage output of the Starbar. Now we shall explain how to compute the electrical requirements to provide the recommended power.

Knowing the wattage output and the resistance of the Starbar you have two parts of an equation with three unknowns. This equation is

V = (W × R), (V = nominal full load voltage, W = rating of the Starbar in watts, R = resistance of the Starbar in ohms). The resistance of the Starbar can be calculated using the values found in Table A.

When solving for V, you would obtain the voltage required on a nominal resistance Starbar to provide the wattage output desired.

Example: A Starbar RR 43 x 24 x 1 has a resistance of 1.27 ohms and 75 square inches of radiating surface. Loading to 38 watts per square inch, this Starbar could provide 2850 watts. To find the nominal voltage, solve for V.

V = (W × R)

V = (2850 × 1.27)

V = 60 volts

Starbars may be connected in parallel, series, or combination thereof. Parallel connections are preferred.

In a parallel arrangement, the voltage across all the Starbars is the same. In the formula W=V²R, (W = watts, V = voltage, R = resistance) it can be seen that the greater the resistance, the lower the wattage output. The Starbars in the parallel circuit with the lowest resistance will supply more heat energy and therefore operate at a higher temperature. This higher Starbar temperature will cause it to gradually increase in resistance until all the Starbars have the same resistance. At this time the Starbars should all have approximately the same resistance values and surface temperatures and therefore remain in balance.

To compute the network resistance of a group of Starbars the following formula may be used: Rn = R x S P (Rn = network resistance, R = resistance of Starbar, S = number of Starbars connected in a series, P = number of parallel circuits).

Example: Eight Starbars RR 43 x 24 x 1

(R = 1.27 ohms) connected 2 in series

(S = 2) and 4 parallel groups (P = 4).

Rn = R x S P

Rn = 1.27 x 2 4

Rn = 0.635 ohms

To compute the nominal voltage required to power a set of Starbars, we shall use a combination of the formulas used in the two previous examples. Vn = (Wt x Rn), (Vn = nominal network voltage, Rn = network resistance, Wt = total wattage output).

Example: Eight Starbars RR 43 x 24 x 1 (R= 1.27 ohms) connected 2 in series, 4 parallel groups. Each Starbar provides 2850 watts. Wt = 8 x 2850 = 22,800 watts. Rn = 0.635 ohms.

Vn = (Wt x Rn)

Vn = (22,800 x 0.635)

Vn = 120 volts

The resistance of Starbars increases gradually during their useful life. Therefore, some means of keeping the power input to the kiln or furnace at a level sufficiently high to maintain the desired temperature is required.

Historically, expensive voltage varying equipment such as multiple tap transformers or saturable reactors were recommended for all but the very low temperature applications.

Starbars can be used directly on the line (fixed voltages) at temperatures up to 2400F

(1315C). To compensate for the reduced output as the Starbars gradually age or increase in resistance, the furnace or kiln is initially overpowered by 25% to 50%. This type of arrangement eliminates the expensive voltage varying equipment and has proven very satisfactory in many applications. It is not recommended when fine process temperature control is required.

Assume a furnace will require approximately 22,000 watts after all heat losses and load factors have been considered. Increasing this 22,000 by 25% to 50% gives a wattage requirement of between 27,500 and 33,000 watts.

By taking another look at the previous examples it can be seen that 10 Starbars RR 43 x 24 x 1 connected two in series, five parallel groups on 120 volts would supply the 28,500 watts. If 12 Starbars of the same size were used, the output would be 34,200 watts. Twelve Starbars connected four in series per phase on 240 volts would make a balanced three-phase 240 volt network.

The temperature of the kiln or furnace is controlled by an off-on controller. When the Starbars are new they will only be powered for 22/28.5 or 22/34.2 of an hour. As the Starbars increase in resistance they will be on for a greater percentage of the time. When they have increased in resistance to a point at which they supply 22,000 watts, they will be on 100% of the time. A SCR (silicon controlled rectifier, or thyristor) can also be used, and can provide precise fine control of the voltage input to the heating elements.

For applications where close temperature control is desired and/or for temperatures above 2400ºF (1315ºC) a device for increasing the voltage to the Starbars is required.

There are several methods of providing this variable voltage source:

(1) The multiple tap transformer was historically the most common. The secondary of the transformer is provided with taps, which usually vary in number from 10 to 36. By carefully selecting the voltage taps, the correct voltage output to match the resistance of the Starbars over their complete useful life can be made.

(2) Silicon controlled rectifiers (SCR, also known as a thyristor stack or thyristor unit) have become increasingly popular, as they offer precise fine control of the voltage input to the heating elements.

(3) A combination of transformers and SCRs, whereby the transformers are used to match the requirements of the load to the voltage supply, but having far fewer taps than conventional transformer only systems, typically 3 to 4 taps only, with the SCR providing the fine control between tap changes.

To compensate for the reduced output as the Starbars increase in resistance, a voltage reserve is required that will compensate for the increase in the Starbar resistance over time. It is quite common to size the voltage reserve to allow the elements to double in resistance and still be able to maintain the desired power output as with new elements. The following formula may be used to calculate Vmax:

Vmax = (Wt x Rn) x 1.5

Vmax = recommended maximum voltage required to compensate for increase in resistance due to aging and resistance tolerance, Wt = rating of transformer in watts, Rn = network resistance of the Starbars, 1.5 = minimum margin to accommodate the doubling of the Starbar resistance and the +20% resistance tolerance. A higher value will offer slightly longer usable service life.

Example: The transformer is rated at 22.8 KVA and has a computed nominal full load voltage of 120 volts. (Rn = 0.635, Wt = 22,800).

Vmax = (Wt x Rn) x 1.5

Vmax = (22,800 x 0.635) x 1.5

Vmax = 180 volts

The nominal full load voltage and maximum voltage have been computed. When specifying the transformer the nominal full load voltage is usually reduced by 5% to 10% to allow for the minus 20% resistance tolerance of the Starbars. Also, lower voltage taps are usually provided for idling and slow heatups.

To calculate the minimum voltage, take 70% of the nominal voltage. For periodic applications, take 30% of the nominal full load voltage.

When computing the size of the voltage steps between taps, a value of 5% of the nominal full load voltage is often used. When SCR or thyristor controls are used on the primary, fewer taps are required. For example, if 6 taps are used, the idling tap can be 0.7 × nominal voltage, then each consecutive tap would be 14% higher. For 8 taps, the idling tap would again be 0.7 × nominal voltage, each consecutive tap at 9.1% higher than the preceding.

Ease of Replacement

recommended starbar spacing

Service life

Starbars increase gradually in resistance with use. This characteristic of increasing in resistance is called aging. Aging is a function of the following:

- Operating temperature

- Electrical loading (usually expressed in watts per square inch or watts per square centimeter of Starbar radiating surface)

- Atmosphere

- Type of operation (continuous or intermittent)

- Operating and maintenance techniques

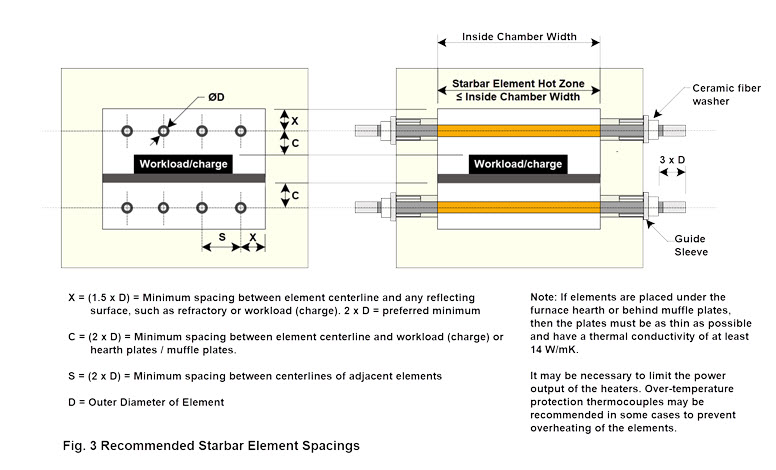

Furnace heating chamber

The furnace heated chamber dimension, which the Starbar spans, can be the same as the hot zone length of the Starbar as shown by the Starbars under the load in Figure 3. Alternately the furnace heating chamber dimension, which the Starbar spans, can be one inch (25 mm) less than the effective heating length of the Starbar. In this case there must be a 45° conical recess in the furnace wall for the Starbars above the load. Recommended terminal hole diameters for various refractory walls and Starbar sizes are shown in Table B.

Starbars should not be placed closer than two Starbar diameters to each other or one and one half Starbar diameters to a wall or other reflecting body. If the Starbar is not able to dissipate heat energy equally in all directions, it may cause local overheating and possible failure.

The formula for computing the recommended Starbar spacing to obtain an even temperature gradient on the product being heated is shown in Figure 3.

Specifications & Matching

Starbars have a manufactured tolerance of plus or minus 20% on the nominal resistance. All Starbars are calibrated at least twice prior to shipping to ensure their being within specifications. The calibrated amperage of each Starbar is marked on the carton and right hand end of each Starbar. When installing, arrange Starbars with amperage values as close to each other as available. Longer service life will be obtained when series connected Starbars are matched in resistance. Starbars are shipped as closely matched as possible.

availabilty

custom conFiguration

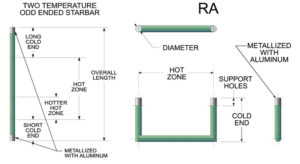

Special sizes and shapes are available. Cold ends can be different lengths. This, for example, would be applicable for furnaces with arched roofs that require longer cold ends through the roof and shorter through the floor.

REQUEST INFORMATION